Safety Footwear and Ergonomics: The Impact of Lower-Limb Fatigue on Productivity and Worker Health, and the Implications for Footwear

Introduction

Workplace fatigue affects 38% of workers across the economy and is estimated to cost businesses in the U.S. over $101 billion in lost productivity each year.1 Industries with work forces that are required to stand for prolonged periods or perform more physically demanding tasks have higher levels of fatigue than other sectors of the economy.

Why is Lower-Limb Fatigue Important?

The impact of fatigue on worker productivity is often only considered at the central level; however, in workplaces that require prolonged standing and physically demanding tasks, fatigue at the local level including the lower limbs can have a major impact on productivity and worker wellbeing. In a study of 407 manufacturing workers, 68% of workers reported lower limb fatigue.2 Lower limb fatigue also affected 34% of the workers' activities outside of work, and 20% were seeking medical treatment for their symptoms.2 Additionally, workers that reported lower limb fatigue also reported poorer workplace engagement and job satisfaction.2 Implementing workplace policies and procedures to minimize lower limb fatigue are required to maximize productivity and improve worker wellbeing.

Causes of Lower Limb Fatigue in the Workplace

Walking and Standing

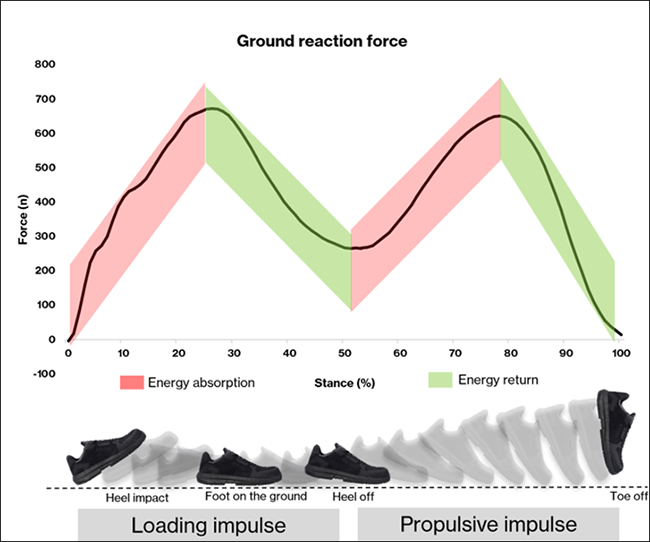

Lower limb fatigue at work is considered to be caused by two factors. The first is repetitive and prolonged muscle contraction during the workday due to walking. When walking the body must perform several contrasting functions. During the loading phase it must absorb any impact forces and adapt to the surface and, to achieve this, it uses synchronized motion between the joints in the foot and leg through controlled muscular contraction to dampen impact vibrations. During this phase the muscles and tendons store elastic energy that is returned when the musculotendon unit recoils during propulsion. In synergy with this elastic recoil, the muscles contract to propel the body forward.

The second factor in fatigue generation is the build-up of metabolites or waste products due to the pooling of blood in the lower limbs during prolonged standing.3 Interventions to minimize workplace fatigue need to be harmonized with the function of the body and address the multiple factors which are related to lower limb fatigue.

Footwear Design

In many industrial workplaces, safety footwear is worn to protect against traumatic foot injuries. However, poor safety footwear design is a significant contributor to workplace fatigue. For every 100g that is added to the foot, oxygen demand is increased by 1 percent due to the additional muscular work required to move the excess weight.4 Safety footwear designs can vary in weight by as much as 300g per side for comparable styles, which is enough to make meaningful differences to workers’ level of fatigue. Stiff footwear designs also alter the power generation tactics of the body by reducing ankle power generation and increasing hip and knee work, resulting in reduced walking efficiency.5 Hard soled safety footwear also increases the risks of developing lower limb fatigue by 2.6-times compared to cushioned safety footwear.2 This increase is comparable to the increased risk of lower limb fatigue in workers with a history of lower extremity osteoarthritis.2 Hard working surfaces are also associated with increased levels of worker fatigue due to the lack of shock attenuation. Optimizing footwear design to minimize fatigue generation presents the most cost-effective intervention available in order to reduce lower limb fatigue at work.

How Can You Reduce Lower Limb Fatigue in the Workplace?

Footwear Weight

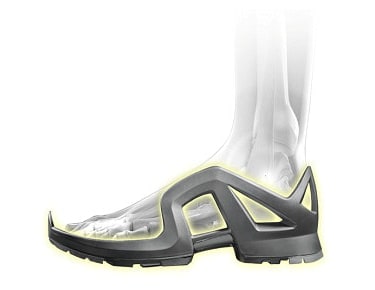

Safety and occupational footwear can play a key role in reducing workplace fatigue. Safety footwear can be manufactured with lightweight composite safety toecaps that can be 40 percent lighter than steel toecaps. Due to the distal location of the toecap weight reduction in this location has the greatest impact on muscular work. Overall footwear weight can be further minimized through clever design and engineering to further reduce its impact on worker fatigue. Footwear designs that are lightweight and provide the necessary protective features for the application should always be prioritized.

Footwear Stiffness

While walking the foot and ankle go through significant motion to adapt to the ground surface and generate propulsive power. Footwear designs that do not allow the required motion can reduce movement efficiency by altering how the body generates power.5 For this reason, stiff footwear should not be equated to providing worker safety.5 Instead, footwear with appropriate flexibility in the forefoot and shaft in the forward/backwards direction should be selected to allow appropriate motion and an efficient walking gait.

Footwear Cushioning and Energy Return

For footwear cushioning to play an effective role in managing workplace fatigue it needs to have functionality that is synchronized with the natural walking gait of the wearer. During walking, the ground reaction forces are characterized by a double hump curve pattern as shown in Figure 1. During the first 20 percent of the ground contact phase the footwear needs to absorb energy during loading and reduce muscle vibration. As the body’s centre of mass moves forward over the weight bearing foot, the footwear needs to return the energy stored in the heel to assist in unloading the rear foot and transferring the weight to the fore foot to begin the propulsive phase. As the fore foot begins to support bodyweight, the fore foot of the shoe needs to store energy and return it during the final 20 percent of the stance phase. Similarly, during prolonged standing, footwear cushioning needs to have high elasticity and energy return characteristics to minimize fatigue development.6 The integration of both shock absorbing and high energy return characteristics makes a meaningful difference to lower limb fatigue in the workplace.

Summary

Lower limb fatigue affects over two thirds of manufacturing workers impacting productivity at work and general worker wellbeing outside of work. Poorly designed safety footwear is a major contributing factor to workplace fatigue, while lightweight next generation footwear can make a meaningful reduction to it. When selecting safety footwear that provides the appropriate level of protection, footwear that is lightweight, flexible, and has cushioning that both absorbs and returns high levels of energy should be selected.

References

1. Ricci JA, Chee E, Lorandeau AL, et al., (2007). Fatigue in the U.S. Workforce: Prevalence and Implications for Lost Productive Work Time. Journal of Occupational and Environmental Medicine 49(1), 1–10.

2. Gell N, Werner RA, Hartigan A, et al., (2011). Risk Factors for Lower Extremity Fatigue Among Assembly Plant Workers. American Journal of Industrial Medicine 54(3), 216–223.

3. Antle DM and Côté JN. (2013). Relationship Between Lower Limb and Trunk Discomfort and Vascular, Muscular and Kinetic Outcomes During Stationary Standing Work. Gait and Posture 37(4), 615–619.

4. Legg SJ and Mahanty A. (1986). Energy Cost of Backpacking in Heavy Boots. Ergonomics 29(3), 433-438.

5. Cikajlo I and Matjačić Z. (2007). The Influence of Boot stiffness on Gait Kinematics and Kinetics During Stance Phase. Ergonomics 50(12), 2171-2182.

6. Cham R and Redfern MS. (2001). Effect of Flooring on Standing Comfort and Fatigue. Human Factors 43(3), 381–391.

5. Cikajlo I and Matjačić Z. (2007). The Influence of Boot stiffness on Gait Kinematics and Kinetics During Stance Phase. Ergonomics 50(12), 2171-2182.

6. Cham R and Redfern MS. (2001). Effect of Flooring on Standing Comfort and Fatigue. Human Factors 43(3), 381–391.

5. Cikajlo I and Matjačić Z. (2007). The Influence of Boot stiffness on Gait Kinematics and Kinetics During Stance Phase. Ergonomics 50(12), 2171-2182.

6. Cham R and Redfern MS. (2001). Effect of Flooring on Standing Comfort and Fatigue. Human Factors 43(3), 381–391.

Content provided by: