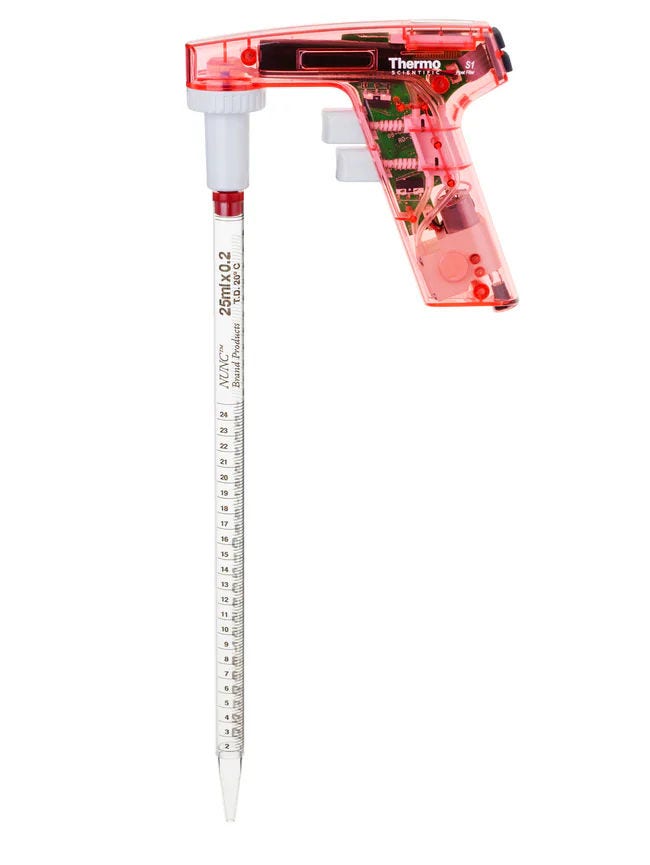

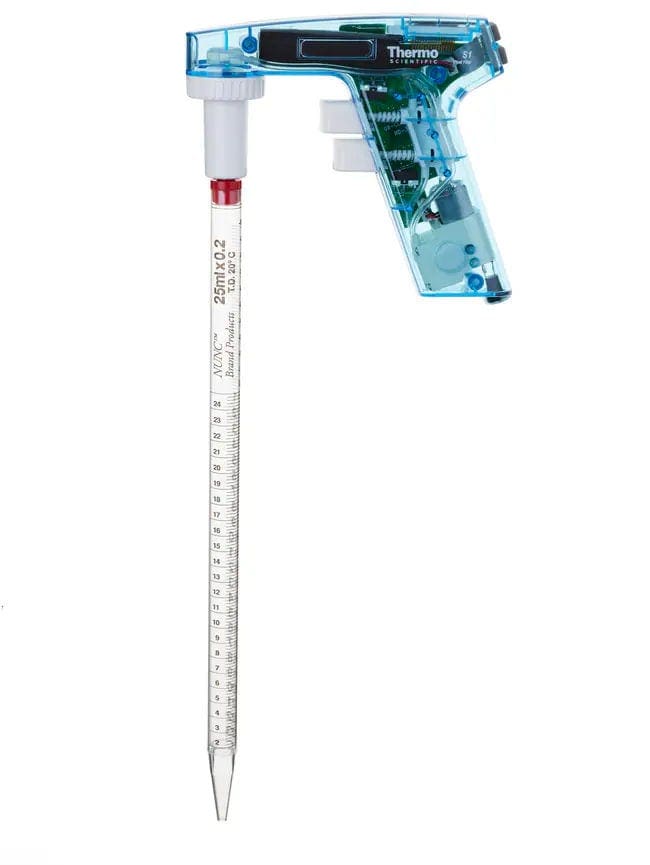

Pipet Fillers

Pipet fillers are essential laboratory tools designed to provide precise and effortless liquid handling. They enhance accuracy and safety by allowing controlled aspiration and dispensing of liquids, making them indispensable for various scientific and medical applications. Their ergonomic design ensures ease of use, reducing hand strain and improving efficiency in the lab

Useful Links

Save Now - Exclusive Deals

Product Code 10367302

Product Code 10626293

Product Code 15128132

Product Code 10028790

Product Code 10060262

Product Code 10193923

Product Code 15219805

Product Code 17334560

Product Code 15840053

Product Code 10593425

Product Code 10210143

Must Have

Product Code 10798252

Product Code 10402822

Product Code 15229805

Product Code 15881827

Product Code 10339051

Product Code 15239805

Product Code 17344560

Product Code 10195551

Complete Your Order - Great Deals

FAQ

Common issues with pipet fillers include air bubbles, leaks, inconsistent liquid dispensing, difficulty in drawing liquid, contamination, mechanical failure, and user error. These can be resolved by ensuring proper attachment and slow liquid drawing to avoid bubbles, replacing worn seals to prevent leaks, regular calibration and cleaning to maintain consistent dispensing, cleaning or replacing clogged filters, thorough cleaning between uses to prevent contamination, regular inspection and maintenance to avoid mechanical failures, and providing proper user training. Regular maintenance and correct usage are key to improving the performance and accuracy of pipet fillers.

To clean and maintain pipet fillers, disassemble and rinse all parts with distilled water, clean with a mild detergent, rinse thoroughly, and disinfect if necessary. Allow parts to air dry completely. Regularly inspect for wear or damage, replace worn parts, lubricate moving parts if recommended, and calibrate regularly. Store the pipet filler in a clean, dry place and always follow the manufacturer’s guidelines for cleaning, maintenance, and use to ensure reliable and accurate performance.

Common issues with manual multichannel pipettes include inconsistent volume dispensing, which can be caused by worn-out seals or improper calibration. Regular maintenance and calibration can help resolve this issue. Leaking can occur due to damaged or improperly seated tips, so ensure that tips are correctly attached and replace any damaged components. Jamming can result from not cleaning the pipette regularly; regular cleaning and proper handling can prevent this. User fatigue is another issue, as manual pipetting can cause hand fatigue over time. Using ergonomic pipettes and taking regular breaks can help reduce fatigue. By addressing these common issues through proper maintenance and handling, you can ensure the reliable performance of your manual multichannel pipettes.